Papertech’s TotalVision™ systems provide machine vision excellence for all kinds of processes, providing our customers with the tools they need to optimize production and stay competitive. Our robust housings protect high-speed digital cameras and components in all types of harsh environments including those found in metallurgical processing plants. TotalVision™ software detects any anomalies or defects, alerting operators to problems that may result in downtime or decreased quality yield. The results delivered have the same benefits we provide to all of our customers – less downtime, less waste, and improved product quality.

TotalVision

Processing Lines

Sheet Finishing

Sheet finishing lines process metal coils used in the manufacturing of automobiles, food containers, appliances, and countless other products. Despite their considerable size and weight, these coils must meet high tolerances for many parameters including dimension, shape, and surface finish.

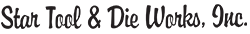

For example, edge trimming is an important step to ensure the coil’s edge is clean, uniform, and the coil’s width is what the customer ordered. To produce high quality trimmed edges, it is important to have the right equipment in good working order.

In this example, TotalVision™ cameras continuously monitor the fine, fast-moving edge. Operator workstations display the magnified edge in real-time along with all metrics important to edge trimming, such as the cut-to-break ratio. TotalVision™ inspection software generates a virtual “map” of each coil as it passes, automatically posting a “defect flag” on the coil map coinciding with the position of identified defects such as chips, lost trims, poor cut-to-break ratio, or other anomalies. But TotalVision™ can monitor more than just edges. If more cameras are required at other line locations, the system is easily scaled. Monitoring cameras are then synchronized to the inspection cameras to allow operators to quickly determine the location and root cause of defects.

Hot Rolling

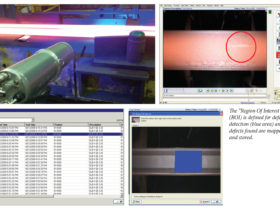

Papertech also provides machine vision systems for hot rolling processes. TotalVision™ cameras and software have proven their value in detecting defects during this manufacturing process. By placing cameras close to the line for an optimal view of the bar as it passes before the guage, operators can view the process safely from a remote workstation instead of conducting a more hazardous post-production inspection on the machine. Our housings protect the camera and all components from the extreme environmental conditions, while high-intensity strobing LED lights ensure optimum quality of images and video.

- One or more regions of interest (ROI) are stored by product ID.

- Ideal product image is stored on the system as reference tool.

- Defects are automatically flagged when current image deviates from reference image.

- Dynamic ROI retains correct position in reference to the bar regardless of bar movement during production.

- Extended video used to frame each part allows operators to select any part and visually inspect top/bottom of part as it was produced.

- All settings load based on product ID. When defects are present, videos are automatically created.